Service Support

APOLLO has been ISO 9001 certification as the unit processing conveyor manufacturers. We have a wide range ofproducts, can be adapted to multi industry use with a wide range of product design, so as to provide customized solutions at cost effective price.

For details, please add WeChat

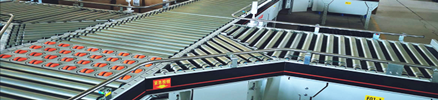

The conveyor system is also known as the transfer conveyor, as a high efficient way, it move and transfer the goods without the use of manual labor to handle goods quickly. The conveyor system can move thousands of parcels per hour and can achieve greater processing efficiency if multiple units are used in parallel.

In the automated logistics center, distribution center and warehouse automation operation, many material treatment sub systems is connected to gether into a cohesive warehouse automation system; conveyor can usually be adapted to a variety of operating environment, suitable purposes, like:

● Transmission

● Stacking

● Sorting

● Loading and unloading

Conveying systems (including belt conveyor, roller conveyor, chain conveyor, sorting conveyor, etc.) can transmit almost anything that is placed on them. Including some common applications: receiving, unloading and sorting, long distance transportation as well as accumulation between kinds of conveyor systems, the horizontal and vertical direction changes.

APOLLO conveying system is fall into three broad categories:Horizontal transportation (belt conveyor, roller conveyor), vertical transportation (spiral conveyor and elevator) and sorting machine (sliding shoe sorter, swivel wheel sorter,swivel arm sorter).

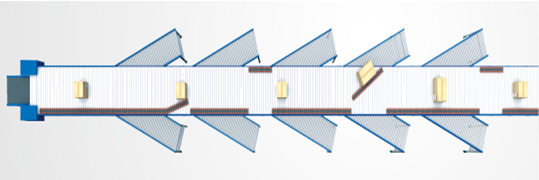

Various conveyor systems provide hands-free movement throughout the material handling process, can adapt to different shapes and sizes of various types include: belt conveyor, roller conveyor, telescopic conveyor, flexible conveyor, turning conveyor, spiral conveyor, chain conveyor and sorter.

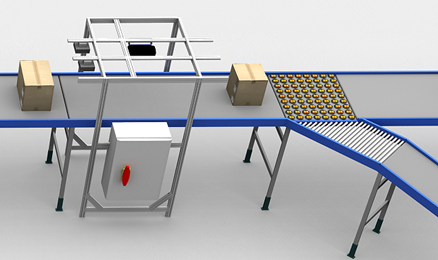

An integrated delivery system provides buffering between automated warehouse operations that operate at different speeds or require segments to be suspended.

The sorting conveyor system has been widely used in recent years. At present, in one or more logistics processes, a method for scheduling and transferring articles in various conveyors in a personalized and automated manner.

The conveyor system integration can handle any item in most companies and select the type of items to be delivered and the process requirements to be performed. Belt and flexible conveyors can be used to handle small or irregularly shaped product or objects that require rapid movement. Roller conveyors are very useful when things are larger. Other determinants include the speed of the project, theefficiency of the process, and the space of the project.

The visibility of all conveyor systems and all related equipment is also important, bec it can achieve high visibility, reduce security risks, and provide the basis for eliminating the automated materials handling system in the transmission and sorting decision.

Warehouse control system software is also important, which is used to integrate the delivery system into the internal logistics system. APOLLO has its own control software, basically can meet all similar software control needs in the market, warehouse implementation software is the key asset to achieve the best performance.

To learn more about the history of APOLLO conveyor system and service we can do for your company, please contact us, we will be happy to share the successful experience of system technology to help improve your operation efficiency.