Spiral Conveyor also known as spiral lifter, it is a lifting or descending equipment with wide range of applications. Compared with other conveying equipment, Spiral Conveyor has the advantages of small space occupation, high throughput, stable and reliable, safe and simple operation, it is the special use machine for goods transfer between different floors.

APOLLO Spiral Conveyor is widely used in logistics warehouse projects, Spiral Conveyor and its infeed and outfeed conveyors form a complete of continuous conveying system. System integrators or users all like the lifter equipment.

Compared with traditional spiral conveyor in the structure, APOLLO has an essential difference. APOLLO adopts modular design and standardized assembly production process.

APOLLO standard slat width has 500mm and 650mm for options which can meet the most of logistics projects. Spiral conveyor can form seamless connection with infeed and outfeed conveyors. Normally running speed is 40m/min, we can even up to 60m/min.Throughput can up to 3500 packages/hour.

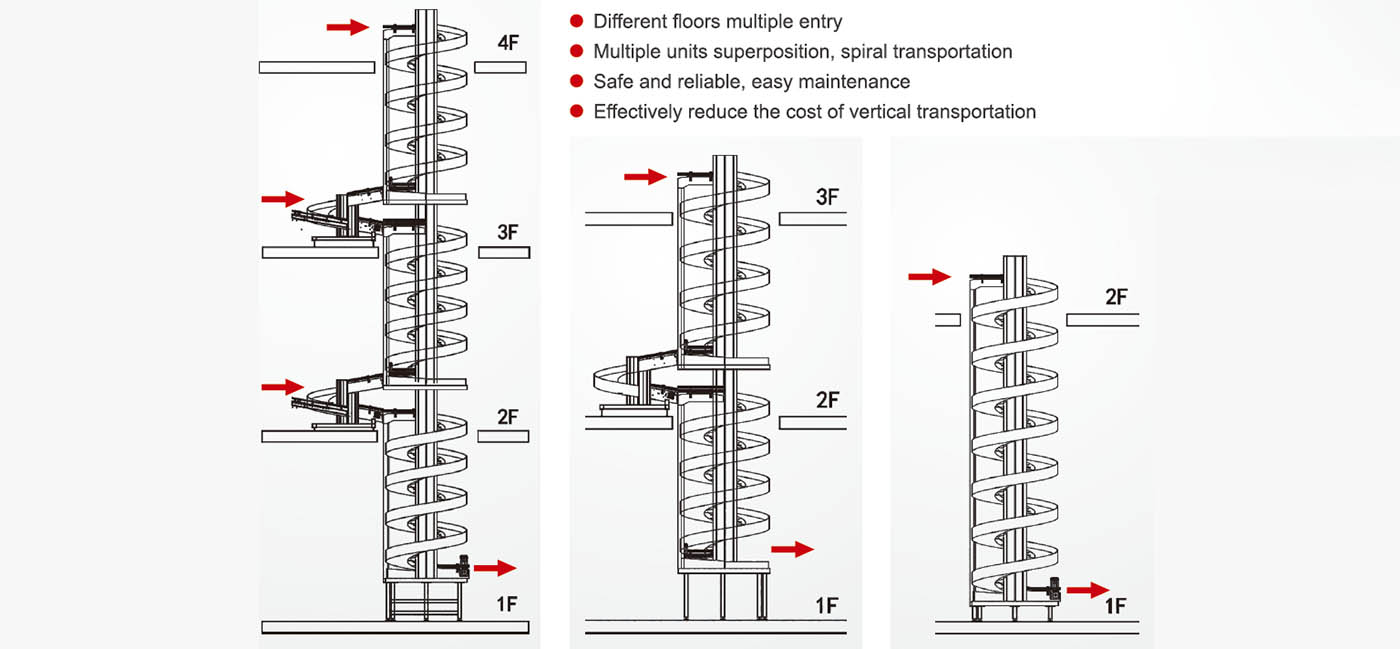

APOLLO Spiral Conveyor also can be superimposed, goods can be transferred between 1-6 floors to achieve the inflow and outflow between multi-layer products which saves the user's space and cost, but also simplifies the overall layout, thus greatly saving space resources and control the system integration costs.

Post time: Nov-04-2019