The automatic sorting project of finished tires in Shengshitailai Rubber realizes the automation and information trace ability of transportation, sorting, palletizing, storage and delivery, as well as directly improving the working efficiency and reducing operating costs for enterprises.

In order to adapt to the development of enterprises and the market demand, as well as improve production efficiency and reduce labor costs, in 2015 Qingzhou Shengshi tailai Rubber Company (herein after referred to as "Sheng Tai") decided the production of 12 million sets of finished tire automatic sorting, through continuous optimization and demonstration project with half year, final confirm the solution for the complete delivery for finished tire storage and sorting system integration.

Shengshi Tailai Rubber

Automatic sorting system for finished tyres

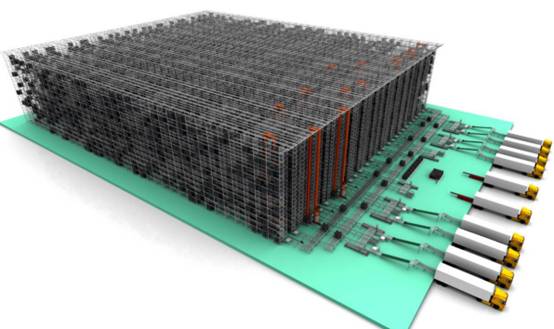

The automated sorting project covers an area of about 21000 square meters, a total investment about 200 million RMB, Shengtai automated sorting project is mainly consists of the intelligent automatic conveying, sorting, automatic stacking, automatic storage system after the detection. Under the realization of ERP information system automation, intelligent and unmanned process, an annual output of 12 million sets of tires meet Shengtai long-term demand and development.

The scheme uses combined rack for storage, total of 14 tunnels, 14 sets more than 30 meters of stacker, the largest inventory of 50400 pallets. Product is transported to the warehouse area in second floor, through the panoramic scanning system of qualified products and unqualified products for automatic sorting, then automatic palletizing robot to storage through transmission lines sent to storage area by 14 sets of stacker machine, on the first floor of the finished tire through the chain roller machine, the telescopic belt conveyor and other conveyor equipment to complete delivery.

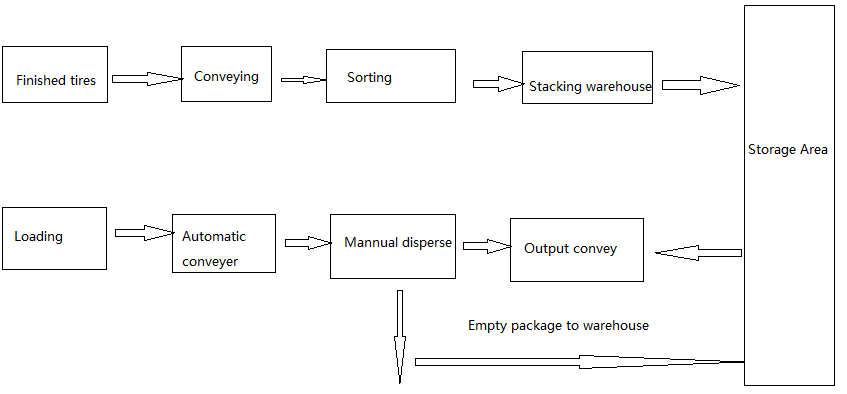

Project overall process chart

1. Finished products storage in warehouse

The finished tire of the workshop is tested by the dynamic testing machine. If passing the inspection, it is transported to the sorting area at the second floor of the vertical store house through the corridor. Defective tiresare delivered to the repair area. Qualified tires after repair again go on the line through the corridor to the two floor sorting area.

The sorting line in the 2nd floor sorting area is sorted according to the specifications to the 12 sorting ports, and the Longmen robot automatically loads the tires to the designated location of the mobile storage desk. When a single tire is piled up over a stack on amobile storage platform, the Longmen robot carries the entire stack of tires toa designated location in the Longmen library. In accordance with the WMS data directive, the Longmen robot carried a stack of tires corresponding to the stack number on to the empty tray. After the storage tray dishfuls of RGV transported to the computer specified, stacker handling to the designated goods shelf.

A: sorting abnormal handling: the sorting machine is equipped with an abnormal over flow outlet, and the finished tire is placed in the abnormal handling port by the manual and then stored in the warehouse.

B: in the stack storage process of appearance detection and bar code review, such as abnormal situation, automatic handling to abnormal handling port, manual processing, and then warehousing.

2. Finished goods Ex- warehouse

After WMS send the shipping instructions, automatic tray stacker place goods to conveyor machine, then annular conveying line send goods to the corresponding delivery port, through artificial plate, label, belt conveyor, vertical tyre, telescopic belt conveyor is transported to the truck for delivery

Empty pallet processing: finished tire tray after separate frompallet, workers will manually send to automatic storage

In the whole system of each tire information tracking, the storage and information can be in full automatic management, to avoid the artificial errors caused by storage and delivery errors, the effective implementation of information traceability, save a lot of operating costs of enterprises, and improve theo peration efficiency.

Post time: Sep-02-2022