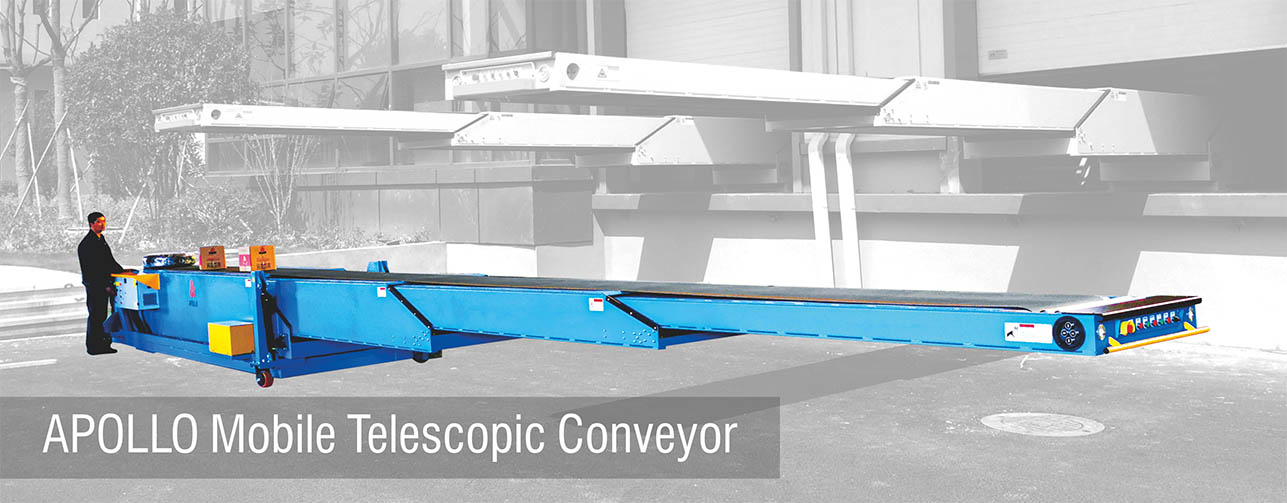

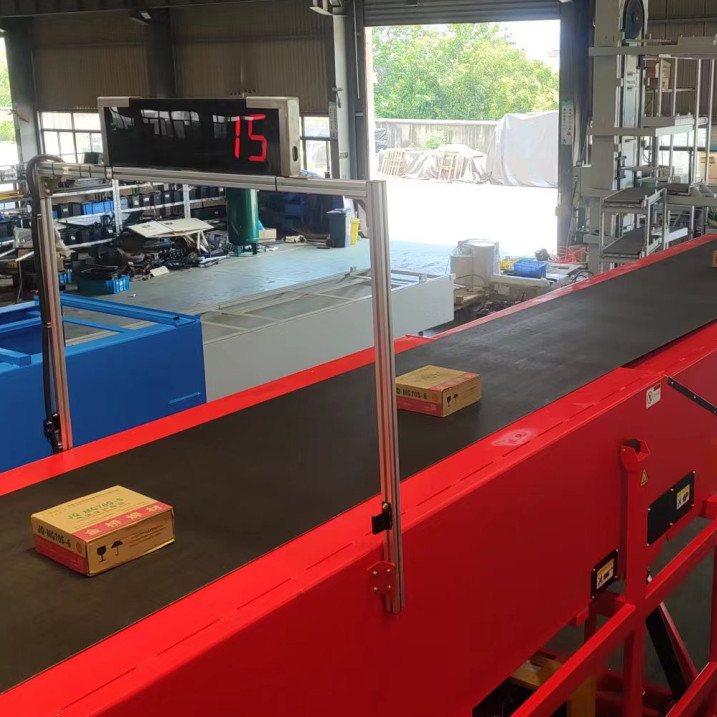

High Chassis Telescopic Belt Conveyor For Dockless Warehouse Loading or Unloading

Industry Applications

High chassis telescopic belt conveyor is suitable for dockless warehouse. This is a complete movable loading and unloading equipment, by manual movement or equip with motorized movement system. Widely used in E-commerce, Third party logistics, Food, Beverages, Pharmaceuticals, Clothes, Furniteure and FMCG etc.

●Suitable for unfixed loading/unloading sites

● Machine can move randomly at ground, conveniently change position according to the goods or the position of the vehicle

● Extra functions are available like hydraulic up/down, light, counter etc

● Mobile type: manual movement, rail traverse movement, motorized movement

● Reduce the damage rate of products, guarantee the safety of goods

● Operation height conform to ergonomic design, easy to handle goods, reduce the labor intensity of workers

● Goods type: carton, bag, parcel, tire, plastic box, barrel etc

● Loading capacity: 50kg/m

When loading and unloading trucks, telescopic belt conveyor makes a world of difference. This solution extends all the way from the permanent conveyor to the nose of the truck trailer or containers, making the process of getting cargo in and out faster, easier and safer, the flexible solution enables the telescopic conveyor to work anywhere in the plant, realizes loading and unloading anywhere.

Large mobile telescopic conveyor weight is about 5 tons, however when choose APOLLO motorized movement type, then no need to worry about moving.

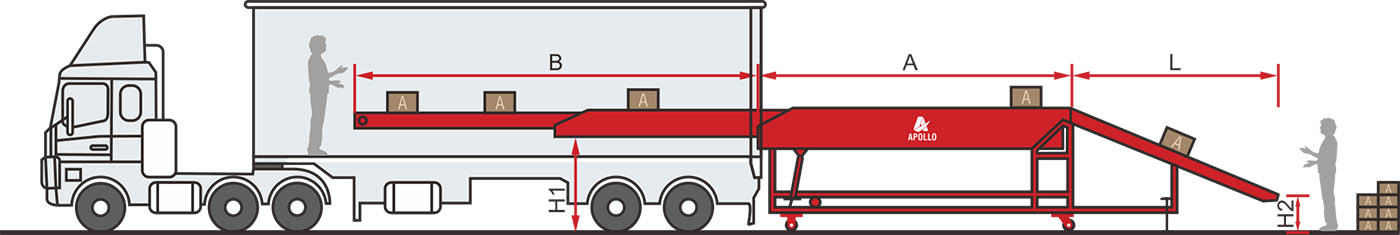

| Model | Sections | Retracted length A(mm) | Extension length B(mm) | Slope L(mm) | Height H1/H2(mm) | Belt width(mm) | nstallation way |

| V3-5+6.5 | 3 | 5000 | 6500 | 4000 | 1600/750 | 600/800/1000 | Fixed / Mobile |

| V3-6+8 | 6000 | 8000 | 4000 | 1600/750 | 600/800/1000 | Fixed / Mobile | |

| V4-5+10 | 4 | 5000 | 10000 | 4000/4500 | 1600/750 | 600/800/1000 | Fixed / Mobile |

| V4-6+12 | 6000 | 12000 | 4000/4500 | 1600/750 | 600/800/1000 | Fixed / Mobile | |

| V4-7+14 | 7000 | 14000 | 4000/4500 | 1600/750 | 600/800/1000 | Fixed / Mobile |

Frequently Asked Questions:

Use non-slip belt for smooth transftor at inclination

Equip with hydraylic cylinders for up/down of the conveyor at front or rear (optional)

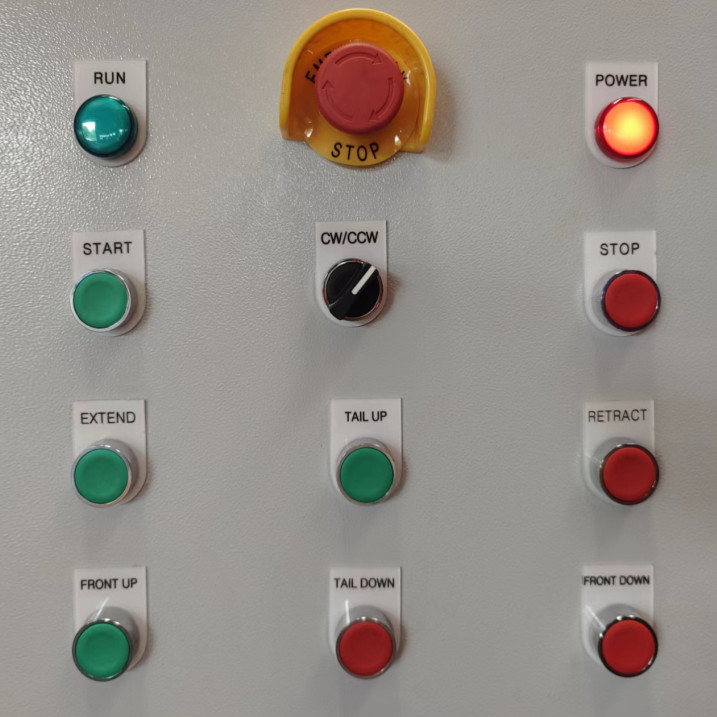

4 directions buttons, easy operation

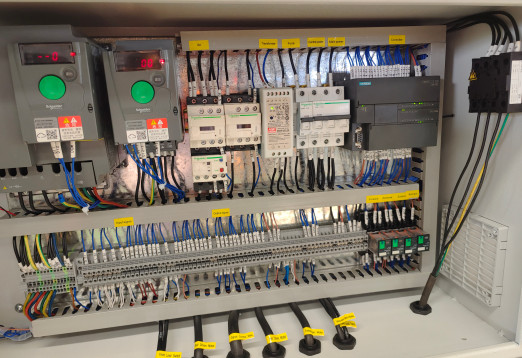

All controls by buttons, obvious and solid nameplate at control panel for clear instruction

Simens PLC control system gets convenient remote maintenance and after-sales service

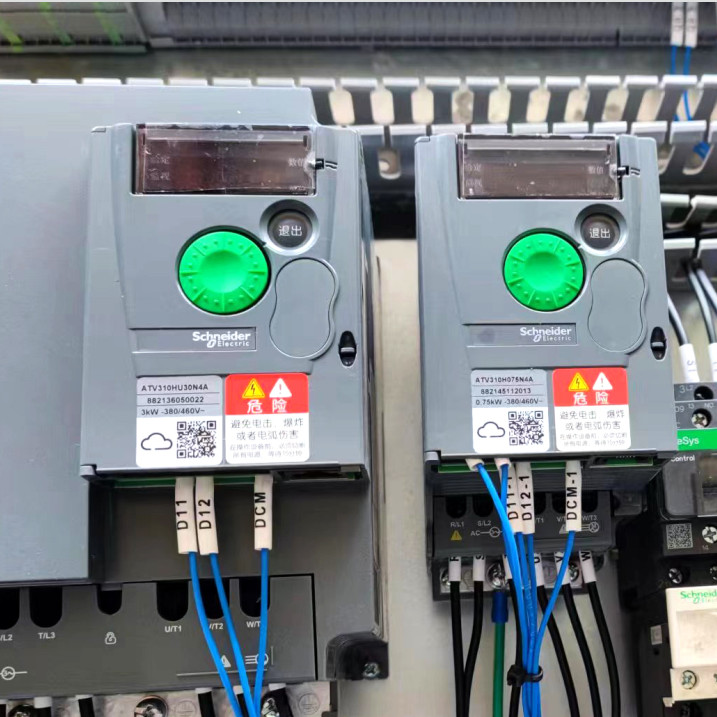

Schneider VFD to adjsut speed, quality stable

Counter with big display is available (optional)

Swing arm at front is available (optional)

Standing platform can be customized for easy mainteance (optional)

Cut steel plate by laser

Bending

Welding

Polishing

Wiring

Assembly

Powder coating

Forming frame

Running test

Finished products

Delivery

In usage at client's site

Our innovation is at your service

Consumer behavior has changed, supply chains have not. Let's talk today to find perfect design and make your loading or unloading more easy, more safe, more efficiency.